General Tool provides superior design and production of your molds ON-SITE by utilizing high tech engineering and manufacturing process with superior quality materials. With 32 years of mold making experience, General Tool meets today's high performance requirements for the plastic molding industry of the future!

Services:

- Plastic Product, Injection Mold and Extrusion Die Design (see partners)

- Mold Flow analysis, Structural analysis, and Consulting

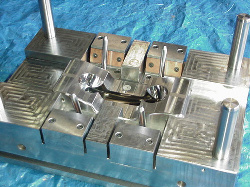

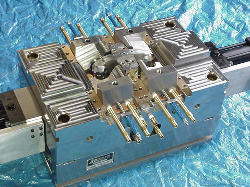

- Large and Small Mold Manufacturing

- Mold Plate and Mold Base Manufacturing

- Extrusion Die Manufacturing

- Prototype Manufacturing

- Mold Revision and Reverse Engineering

- Highspeed Machining

- 3-D Surface Machining of Soft and Hard Metal, Plastic, Nylon, Polycarbonate, Rexolite

- Micro Milling

- Hard Milling

- Conventional Machining

- Vertical Turning

- EDM Services both Wire and Ram

- Gun Drilling

- Polishing

- Mold sampling available upon request

- Artwork

General Tool provides a fully integrated approach to mold manufacturing. From initial concept and/or sketches we can engineer the product, provide 3-D wire frame, surface design and computerized solid models. We can then translate product designs into .STL formats for rapid prototyping which allows you to see and feel your product prior to actual tooling production. Our technology base is constantly changing along with the industries we serve. This allow General Tool to provide you with the best quality product possible, while minimizing costs and maximizing product aesthetics. The better the mold, the better the product!

Our molds are engineered to be "molder-friendly" - keeping its usage and your final product in mind at all times. General Tool designs molds with inserts that are removable while the mold is in the press, practical hot runner systems and maximum water flow to reduce cycle times and ultimately minimize your product costs. We also utilize the best steels and metal alloys available in the market place to improve your mold life and processability. General Tool has a fully staffed engineering department with multiply networked computer stations capable of product design, mold design and mold manufacture. At General Tool, we utilize the latest technology available for information processing including:

- Computer Aided Design (CAD)

- Computer Aided Manufacturing (CAM)

- Design and Manufacturing Software:

Cimatron

Solidworks

Mastercam

Cadkey

- Importing and exporting information via:

IGES Step

Parasolid DWG

SAT STL

ADL DXF

- Successful communication with the following software:

PRO Engineer AutoCAD

SDRC/IDEAS KATIA